Webinar on materials economy and AI

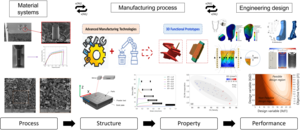

Manufacturing processes account for 54% of the world's energy consumption and 20% of global CO2 emissions. A practical approach to enhance sustainability in production is increasing energy efficiency. The future for sustainable production requires that material science, manufacturing systems, and engineering design are connected, intelligent, and tailored to the application. A promising solution to sustainability lies at the interfaces between material sciences, digital manufacturing technologies, and advanced engineering design methods.

Additive manufacturing (AM) (aka. 3D printing) is inherently a digital manufacturing process that enables disruptive workflows for integrated material system design and manufacturing. AM systems' scientific and technological advantage is that: "Product performance can be maximized through the synthesis of shapes, sizes, hierarchical structures and material compositions, subject to the capabilities of additive manufacturing technologies".

AM makes the manufacture of high-performance and multi-functional and multi-material components, hitherto considered impossible, feasible. It enables the automated manufacturing of parts with complex spatially varying geometries, multi-material systems, and functionally graded structures akin to hierarchical structures or biologically inspired composites like bone or wood.

This short webinar will present the combined research intent of six scholars from Indian Institutes of Technology (IITs) Jammu and Tirupati, Tampere University and University of Turku who are blending their research disciplines towards common goals.

This webinar is organized as part of FICORE Connects! promotional series. FICORE (Finnish Indian Consortia for Research and Education) is an initiative funded and supported by the Finnish Ministry of Education and Culture. FICORE involves 38 higher education institutions from Finland and India.

Date: Friday 13 May 2022

Time: 12.00-14.30 EEST/14.30-17.00 IST

Zoom link for joining - Will be shared through emails for those who registered (Link for registration below the image on the right).

Programme

| TIME (EEST) | TIME (IST) | PROGRAMME |

|---|---|---|

| 11.45 | 14.15 |

Welcome & FICORE in a nutshell Kit Srinivasan, Coordinator FICORE, Global Engagement, Aalto University, Finland |

| 11.55 | 14.25 |

Inaugural Address Professor Manoj Singh Gaur, Director, IIT Jammu |

| 12.05 | 14.35 |

Open additive manufacturing systems Assistant Professor Rajkumar Velu, Department of Mechanical Engineering, IIT Jammu, India |

| 12.25 | 14.55 |

Material science and in-situ micromechanics Assistant Professor Gaurav Mohanty, Faculty of Engineering and Natural Sciences, Tampere University, Finland |

| 12.45 | 15.15 |

Recent Advances and Challenges in Wire Arc Additive Manufacturing (WAAM) of Ferrous and Non Ferrous Materials Assistant Professor Ajay Kumar, Department of Mechanical Engineering, IIT Tirupati, India |

| 13.05 | 15.35 | BREAK |

| 13.15 | 15.50 |

Research activities in additive and related layer-by-layer manufacturing processes at UTU Assistant Professor Ashish Ganvir, Department of Mechanical Engineering, University of Turku, Finland |

| 13.35 | 16.10 |

Surface integrity in advanced manufacturing processes Assistant Professor Anand Kumar, Department of Mechanical Engineering, IIT Jammu, India |

| 13.55 | 16.30 |

Predictive modelling in materials and manufacturing Professor Inigo Flores Ituarte, Automation Technology and Mechanical Engineering, Faculty of Engineering and Natural Sciences, Tampere University, Finland |

|

14.15 14.30 |

16.50 17.00 |

Open discussions, next steps and wrap up End of webinar |